Markforged Industrial Series: X3

The Markforged X3 is a plastic 3D printer that used chopped carbon fiber filament reinforcement to produce parts that are 20% stronger and 40% stiffer than ABS. Resistant to impact and a wide variety of manufacturing chemicals. These heavy duty parts stand up to abuse. The X3 is designed to just work. Fully instrumented with motor encoders and a laser micrometer 3D scanner. Exceptionally accurate, consistently reliable, and repeatable. This cost-effective 3D plastic printer meets the needs of a huge range of industrial applications.

Markforged Industrial Series: X5

Now you can 3D print fiberglass parts faster and cheaper than machining. For load bearing applications that require real strength, these parts make the grade. 20x stronger and 10x stiffer than ABS. For applications where weak doesn’t cut it, these parts are perfect for a wide variety of tooling, fixtures, and functional prototypes. Replace mission critical machined aluminum with fiberglass 3D printed composite parts at 1/20th the cost. These tough parts nail the sweet spot of strength and affordability.

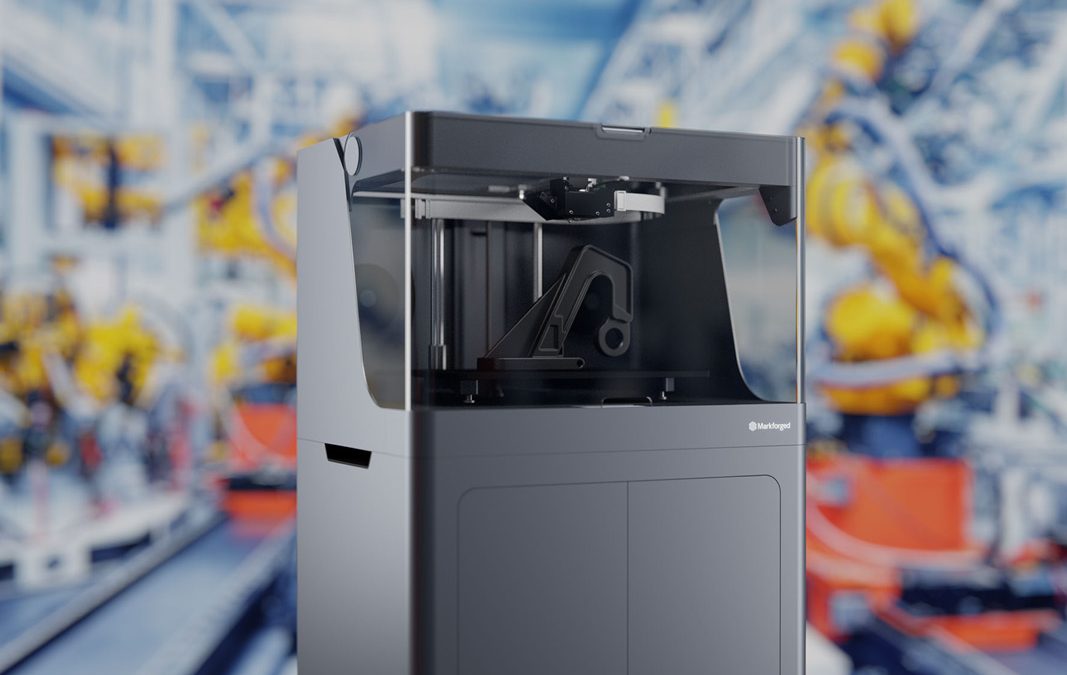

Markforged Industrial Series: X7

Exceptionally strong, supremely stiff, ultra lightweight, and incredibly versatile – X7 3D printed parts deliver unparalleled performance without compromise. Continuous carbon fiber parts stand up to the toughest applications. Stronger than 6061 Aluminum and 40% lighter, these parts are perfect for manufacturing equipment, jaws, tooling and end use parts. Directly replace machined aluminum with parts straight off the X7 3D printer. Parts printed with Onyx and reinforced with carbon fiber filament, fiberglass or Kevlar are work capable and ready the same day for a fraction of the cost.